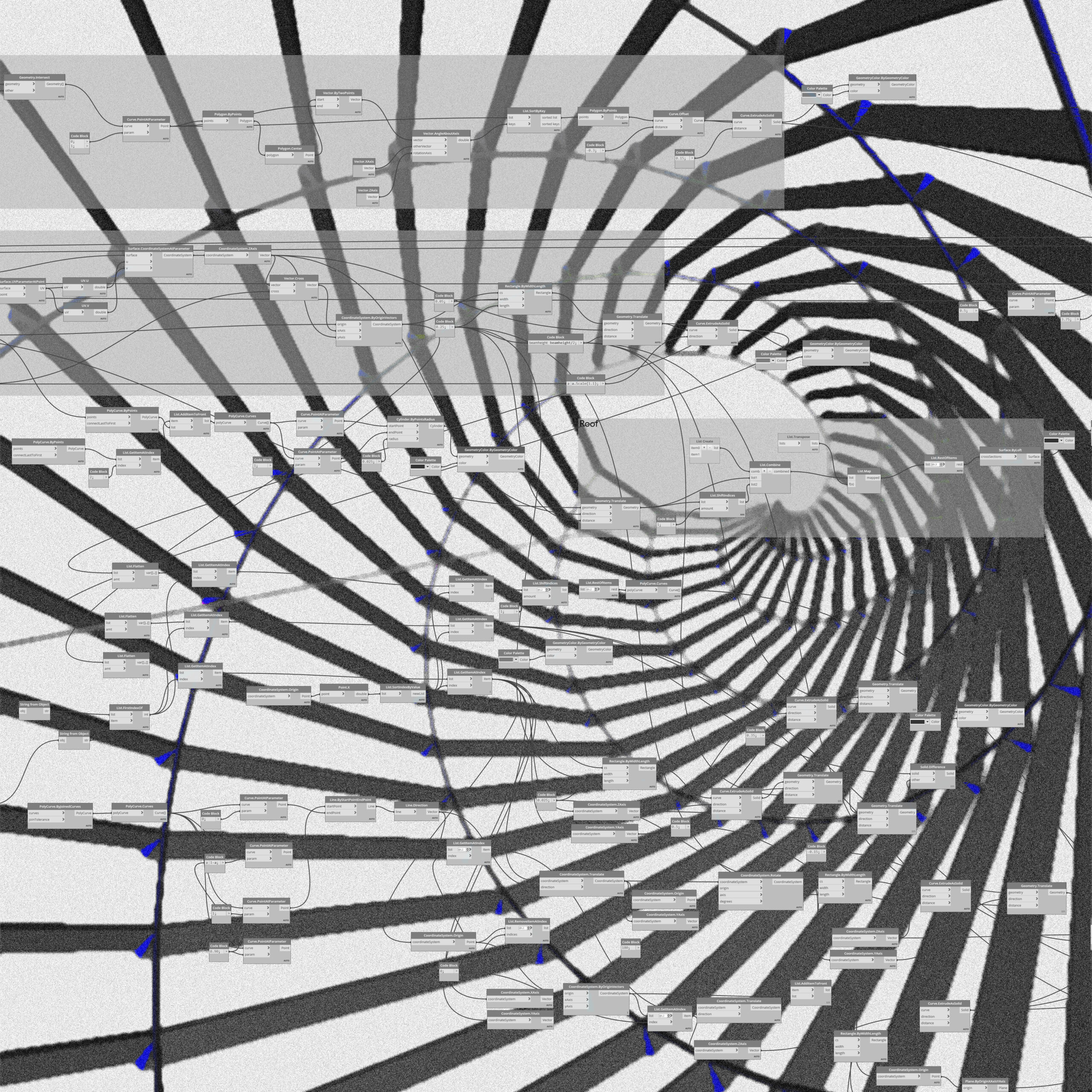

Computational

Architect

Expert on Facade Digital Fabrication / Parametric Modelling

What I can do for you

I specialize in complex building projects that require coding to automate tedious tasks. The goal is always to save time and manpower with utmost accuracy.

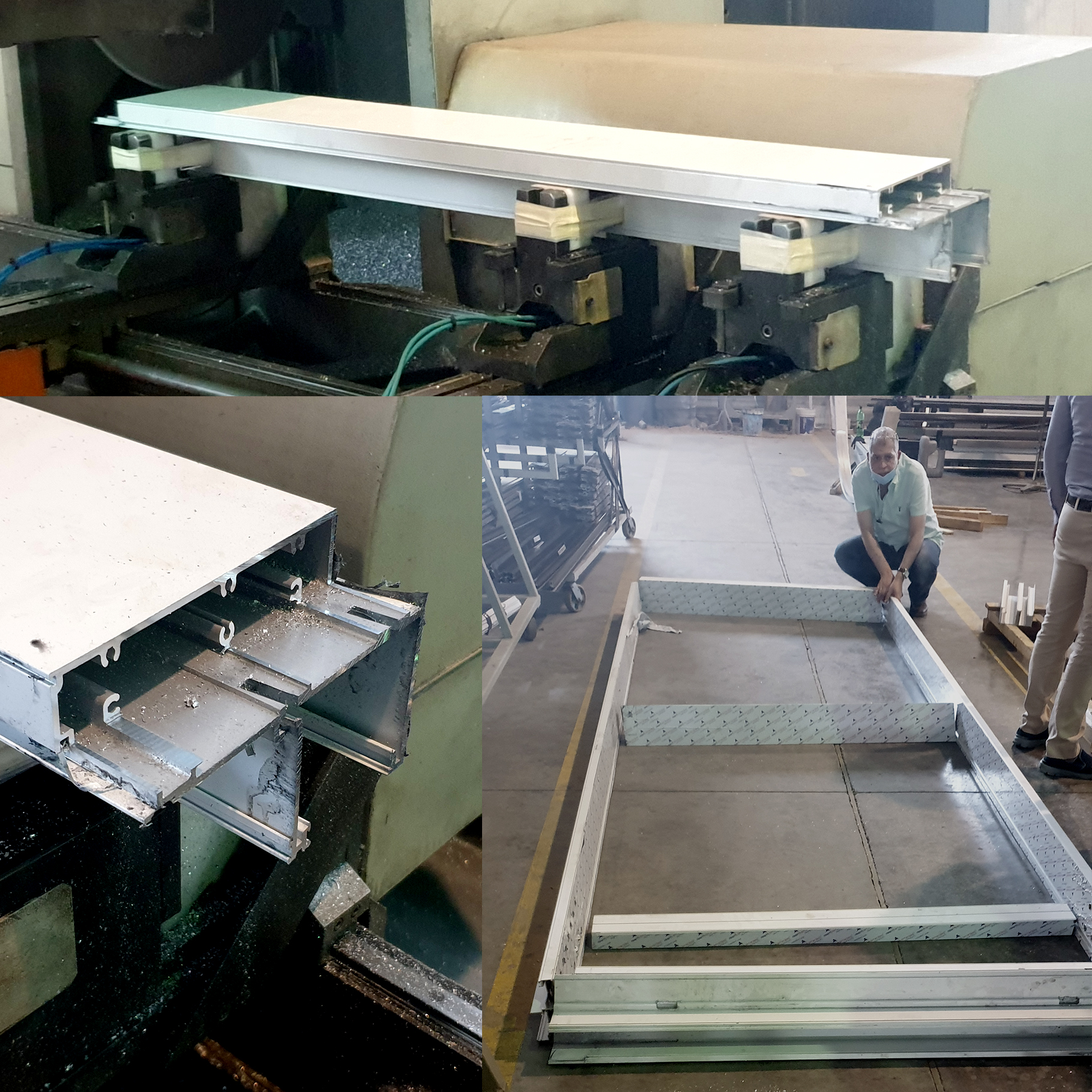

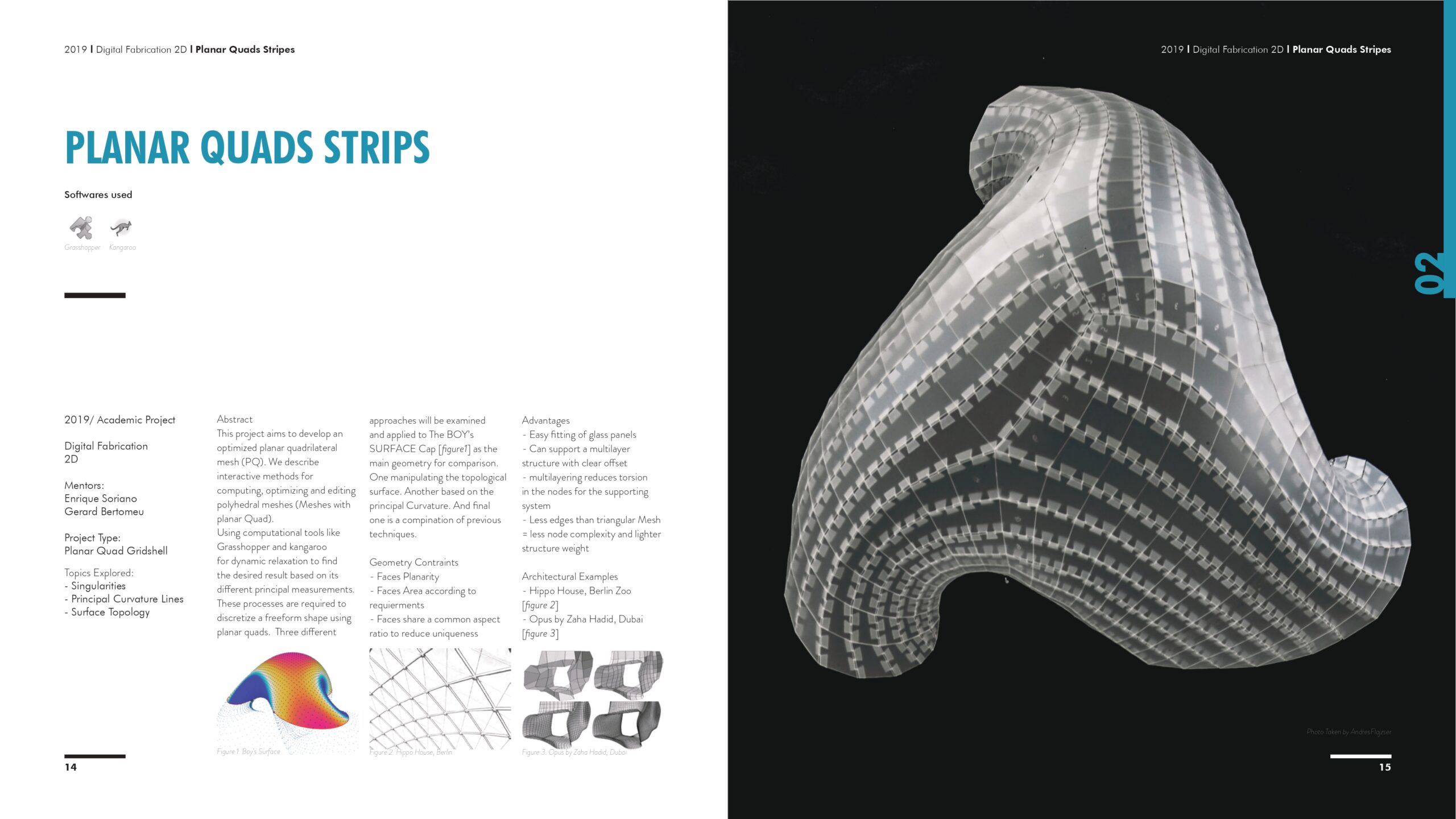

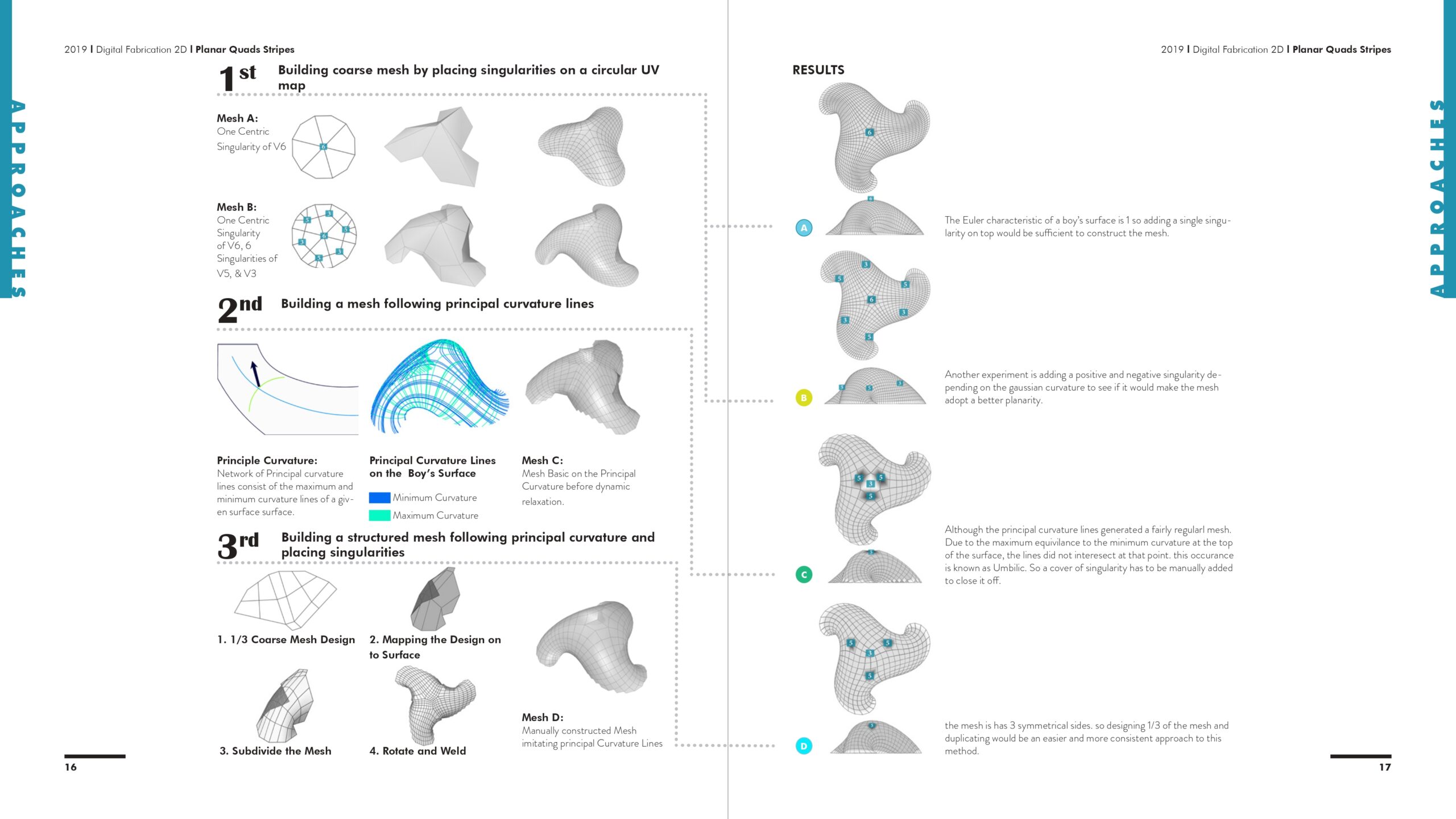

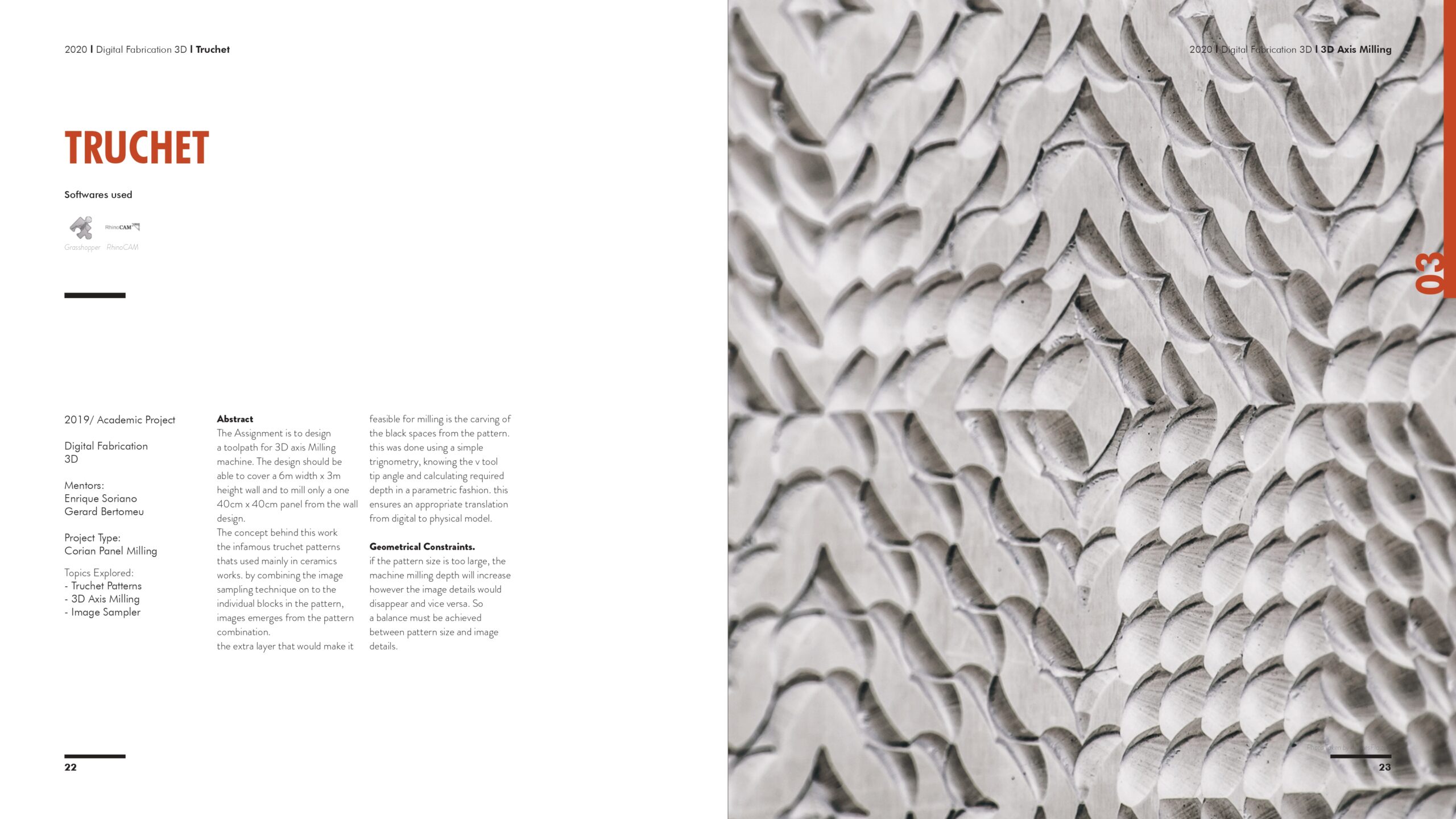

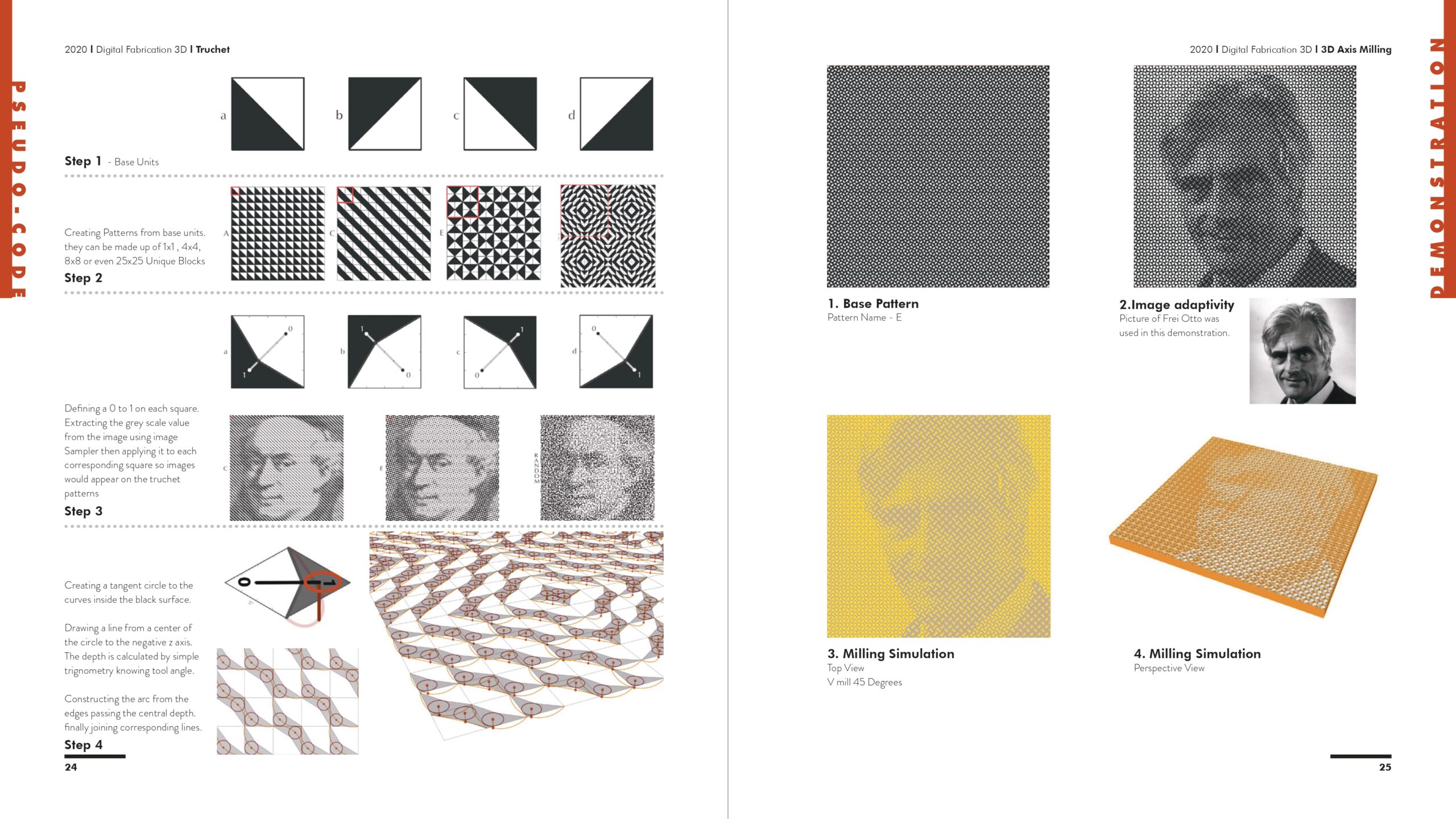

Digital Fabrication

Creating fabrication orders and 3D models for building systems. The process is efficiently automated for non-typical facade systems. This allows the machining & assembly processes to be easily categorized and regulated through out.

BIM Modelling / Management

Complex building systems require advanced techniques of parametric design in order to be quickly and efficiently modeled. Also software interoperability is used for easy coordination with other disciplines.

Design Optimization

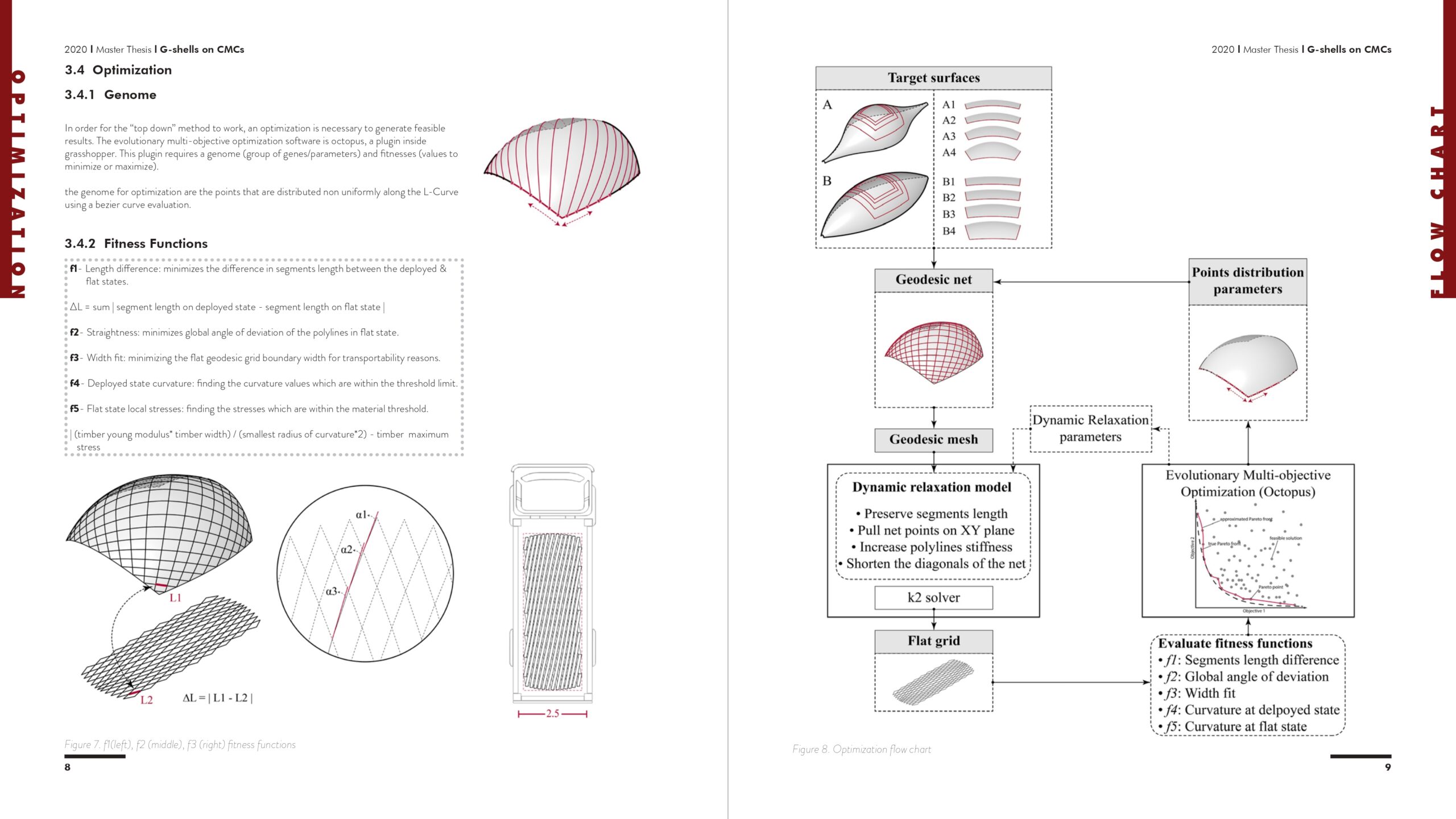

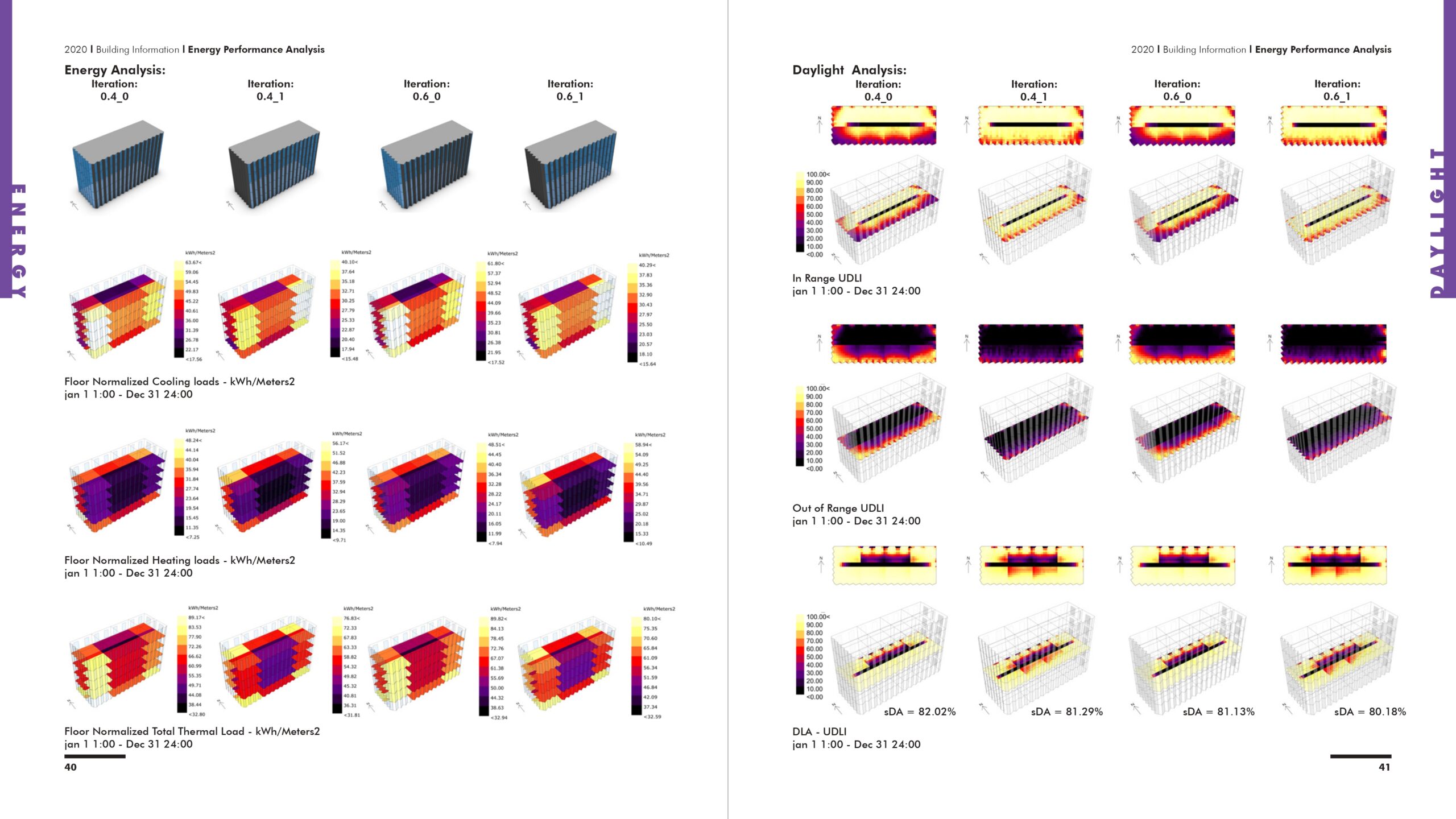

Optimizing fabrication and environmental design can help in cutting time and reducing the overall cost of the project. This is done through optimization engine simulations with fitness objectives.

Resume

HEROES ARCHITECTS & ENGINEERS

Senior Computational Architect | September, 2022– Present Dubai,UAE

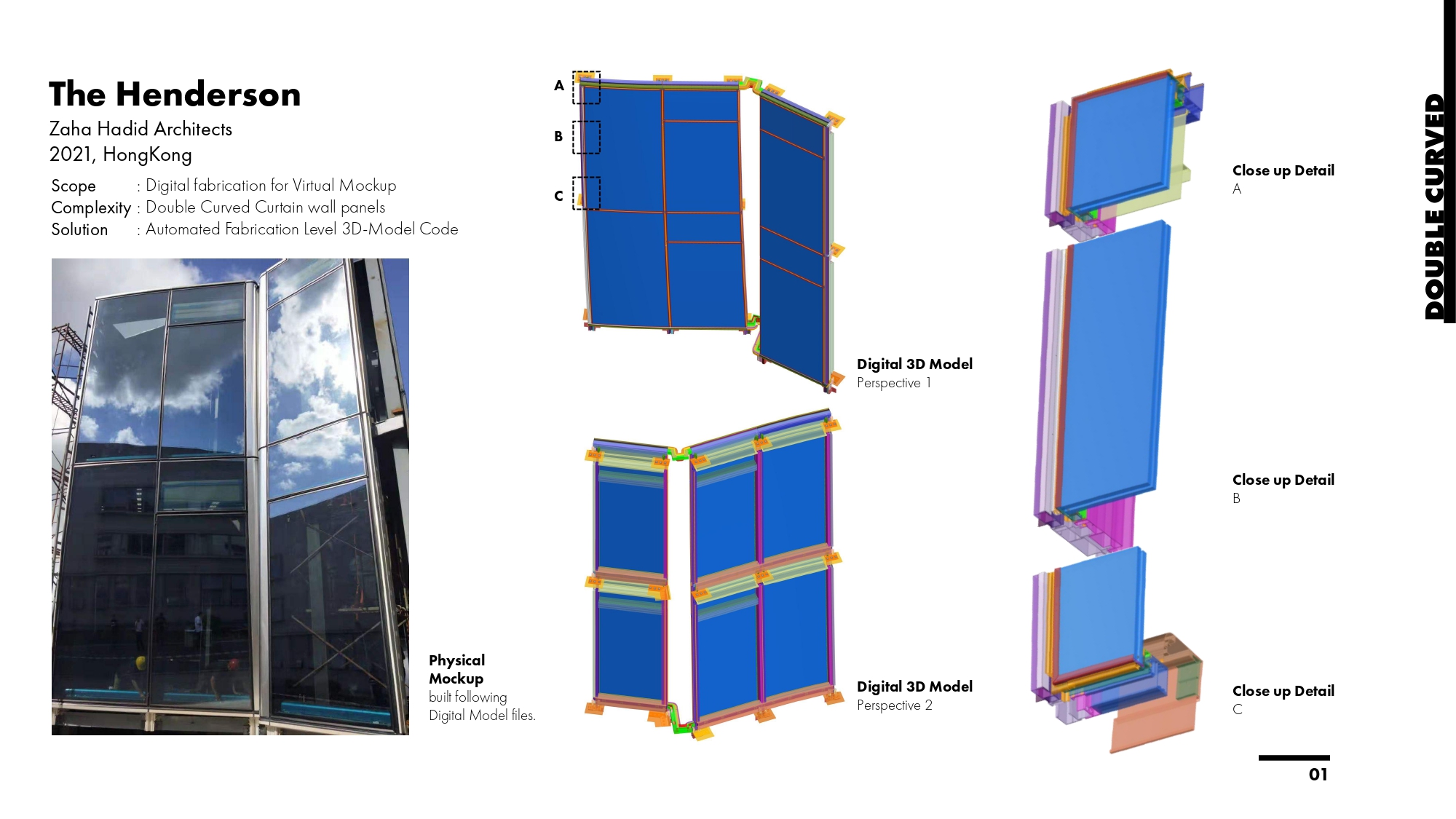

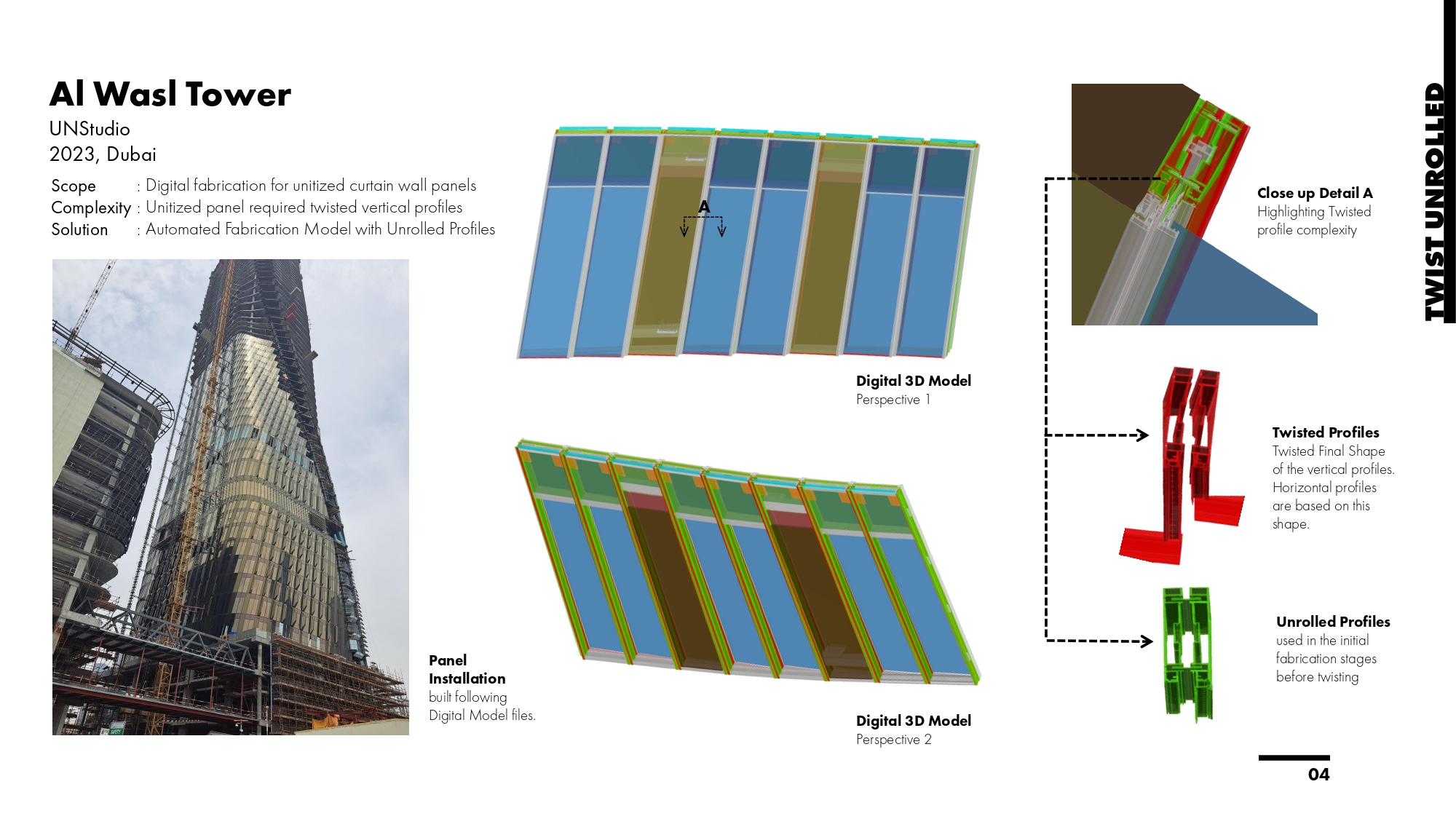

- Managed teams to work on the digital fabrication and/or BIM of complicated facade projects such as The Henderson by Zaha Hadid, Al Wasl Tower by Unstudio, ILMI Science Museum, and Fifteen Fifteen Skyscraper.

- Developed workflows for the teams in order to handle complex tasks accurately, save time and manpower.

- For the digital fabrication scope, created grasshopper codes to automate the production of fabrication 3D models, drawings and work orders.

- For the BIM scope, created Dynamo and Rhino.inside.Revit codes to automate the modeling and tagging of complicated geometry and have a seamless transition to other design softwares.

- Coordinated BIM models on online platforms such as BIM 360 , Aconex and ACC following BIM Execution Planning Standards of their respective projects.

- Customized the output of the work with every project to meet their specific requirements and have smooth approval of deliverables.

- Organized training for the staff in Rhinoceros 3D, Grasshopper 3D and Revit to improve the efficiency and quality of the deliverables by adhering to the established workflows.

Medior Computational Architect | October, 2020– September, 2022

- Prior to being promoted to a Senior position, I was managing a small team for one project at a time. Creating automated workflows and codes to deliver 3D models and drawings for facade super accurate and fast.

UNIVERSITAT POLITÈCNICA DE CATALUNYA

Professor Assistant for the Master Architecture Course (Part time) | October, 2019– October, 2020 Barcelona, Spain

- Assisting the professors with administrative tasks and helping students with understanding lectures and assignments which resulted in a full rate of assignment completion rate.

Code: Grasshopper 3D, Dynamo , Python, Rhino inside Revit.

3D Modeling: Rhinoceros 3D, 3D Studio Max, AutoCAD, SketchUP.

BIM: Revit, BIM360, Aconex, Construction Cloud.

Post Processing/Editing: Lumion, Photoshop, Indesign, V-Ray, DSLR Photography.

3D Printing: Cartesian (FDM) printer, Stereolithography (SLA) Printer.

UNIVERSITAT POLITÈCNICA DE CATALUNYA | Barcelona, Spain

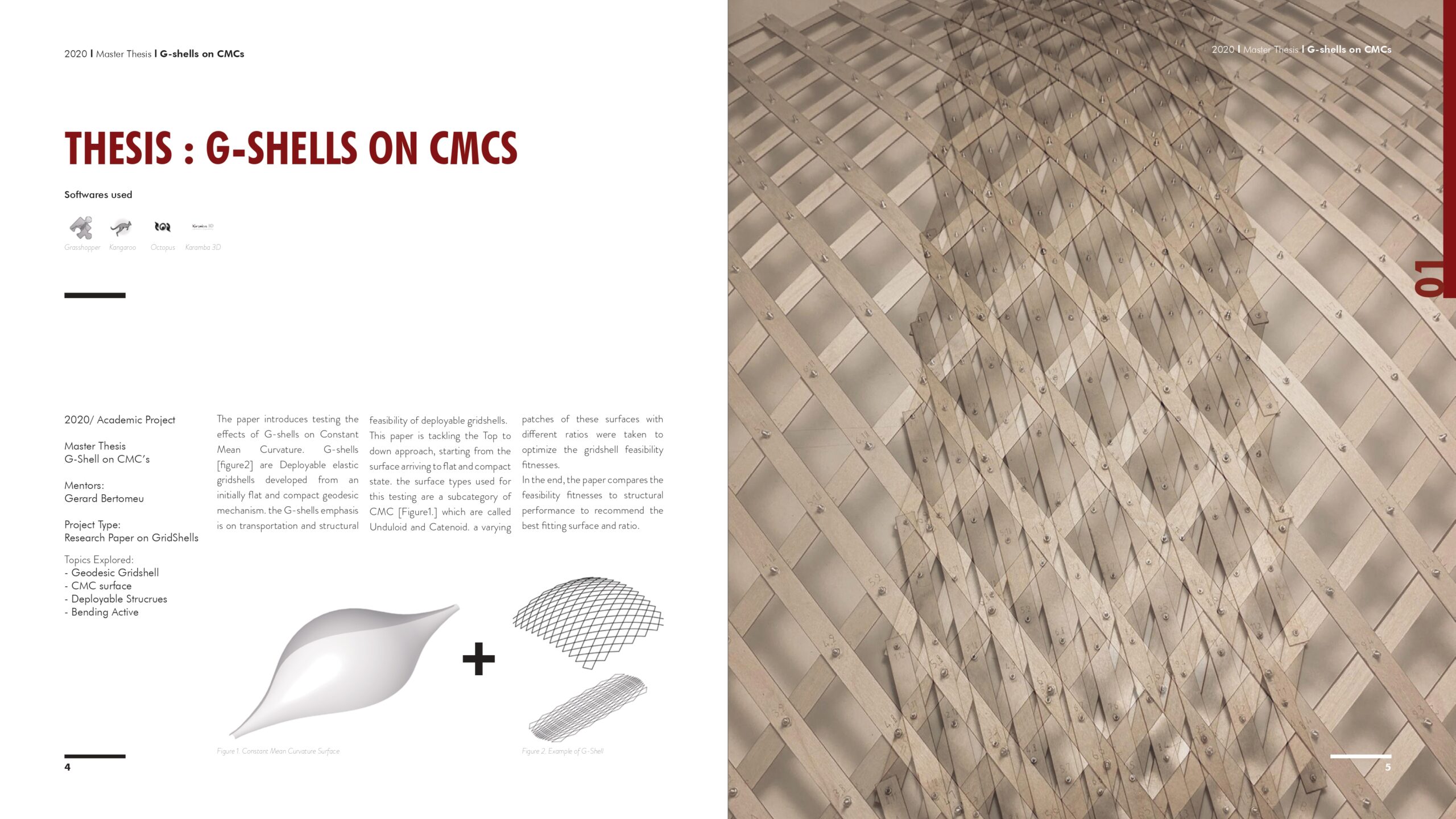

Master in Parametric Design in Architecture, Average : 9.2/10 May 2020

AMERICAN UNIVERSITY IN DUBAI | Dubai, UAE

Bachelor of Architecture, Honors Cum Laude : 3.6/4 (CGPA) May 2018

portfolio

Each portfolio provides a visual resume of varying scopes. Professional Work showcases the most complicated facade projects worked on. While the Other Coding Projects shows an in-depth analysis of design and coding methodologies.

Demo videos

Quick snippets of codes created to majorly help solve sticking points in every project to reduce time and maintain client schedule.

The task was to automate the generation of fabrication drawings for aluminum profiles. These profiles were unique as they require 4 Axis cut angles. The code operates in three steps: First, orienting and adding dimensions necessary for fabrication. Second, putting them into sheets for printing with appropriate scale. Then finally exporting to PDF and STP.

The task was to automate the generation of assembly drawing for cladding subframe profiles. These profiles require item numbers, coordinates and dimensions. In this code, there were three parts: First, 2D snapshot and adding tagging necessary for assembly. Second, Putting them into sheets for printing with appropriate scale. Then finally exporting to PDF.

The task was to automate fabrication order cover page. The data is extracted directly from the model to fill in the inputs for fabrication. This establishes a workflow directly from 3D fabrication model to production.

The task was to automate the production of an intricate exploded view for any curtain wall system panel. This code can work on all panel types, in a systematic manner, to similarly display the components for demonstration purposes to the client.

The task was to control the curtain wall grid from rhino. The main architect design tool was rhino but needed a reliable method to transfer the modulation and design updates into Revit. Hence, a code was developed to automatically extract & articulate this information.